How it Works

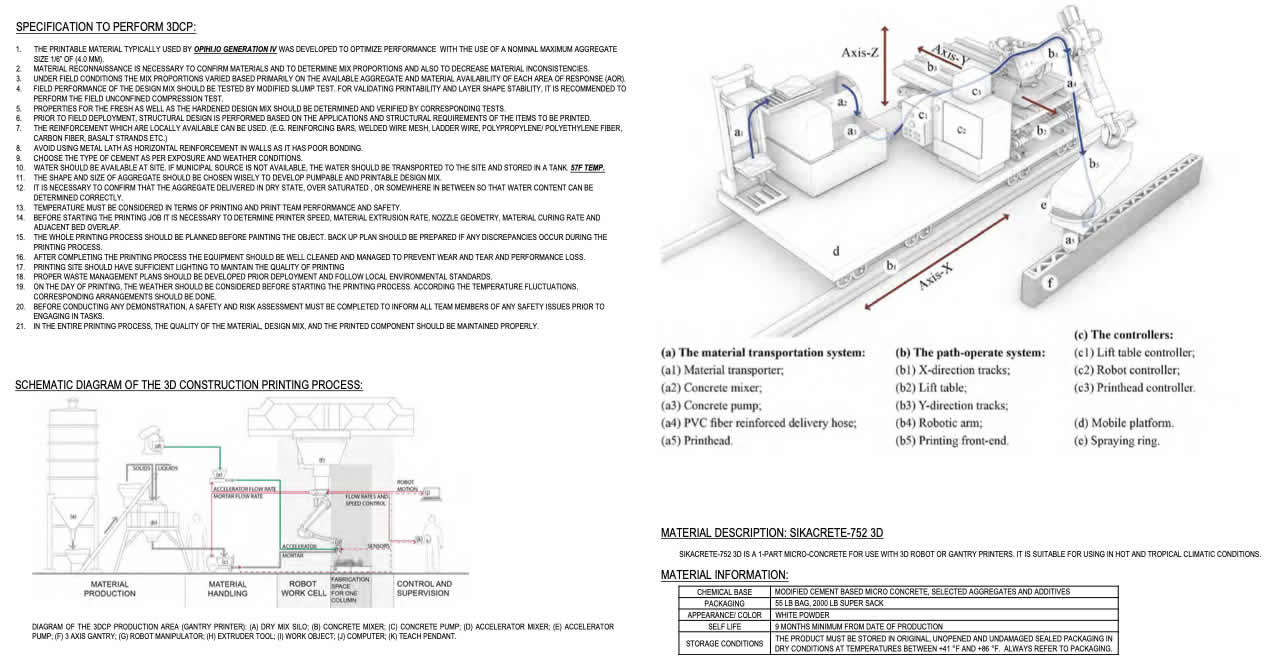

3D concrete printing works much like a regular 3D printer

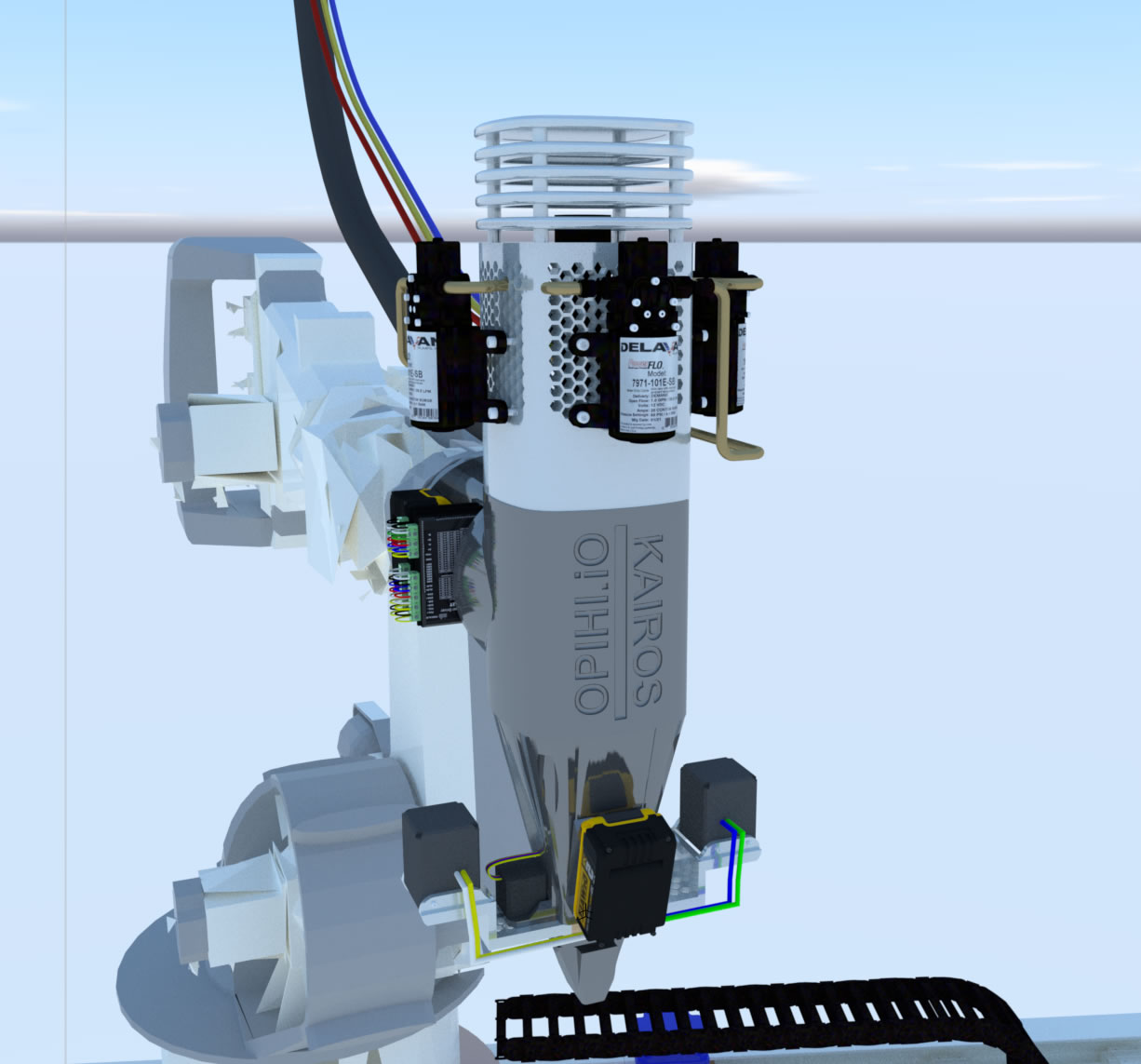

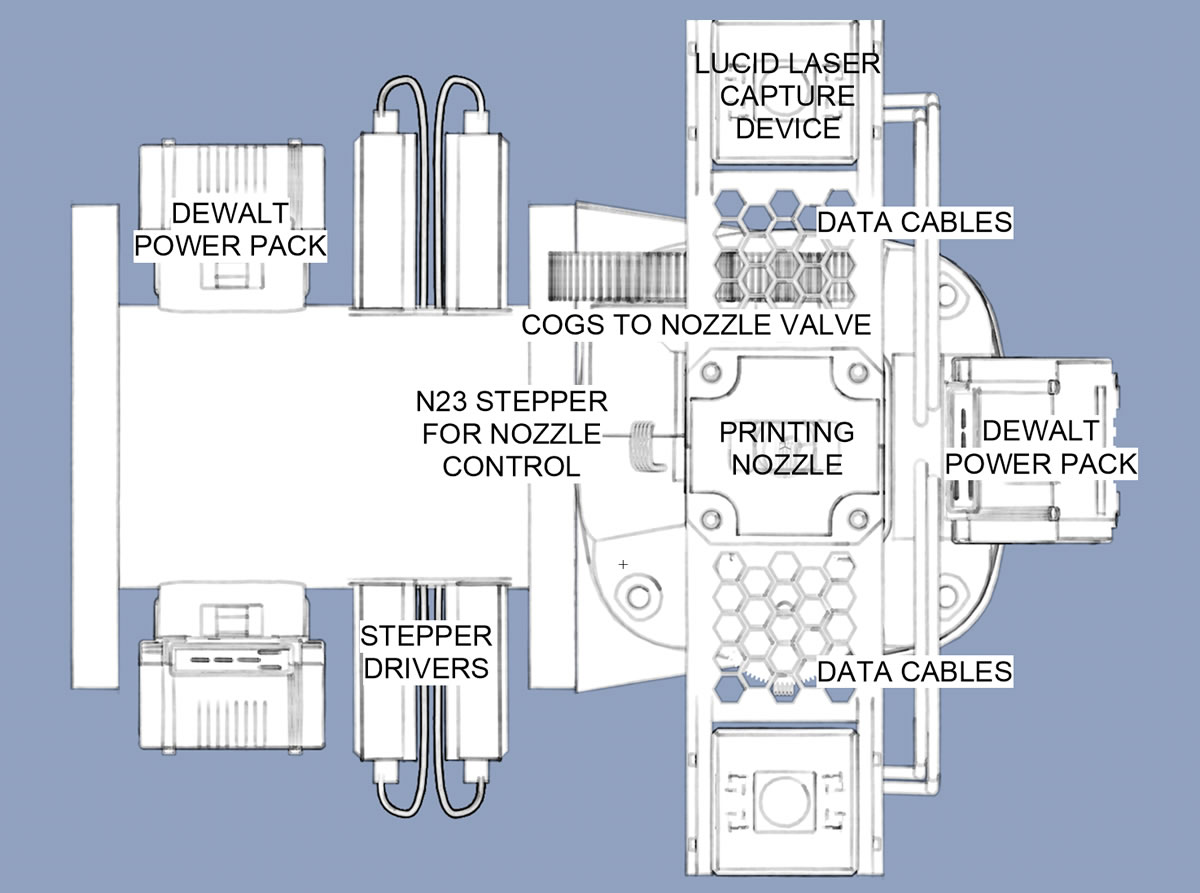

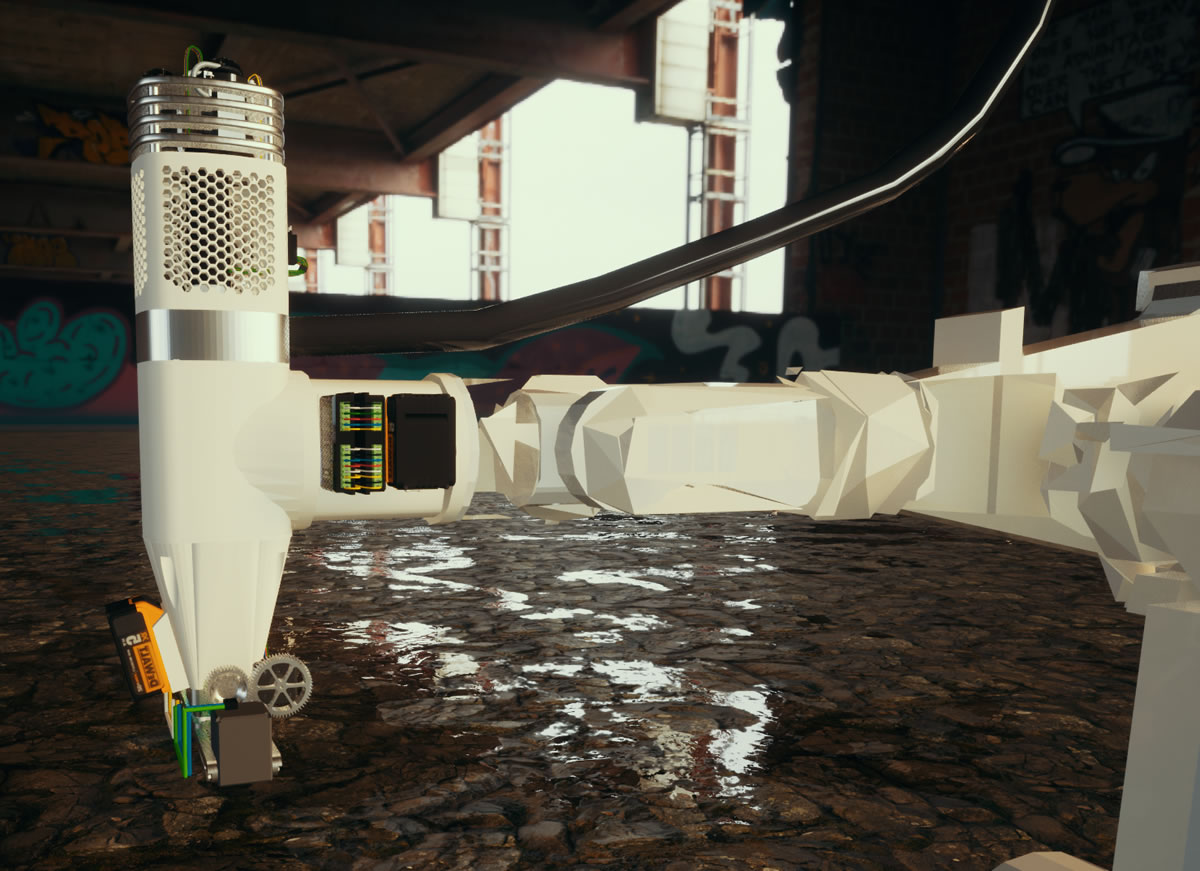

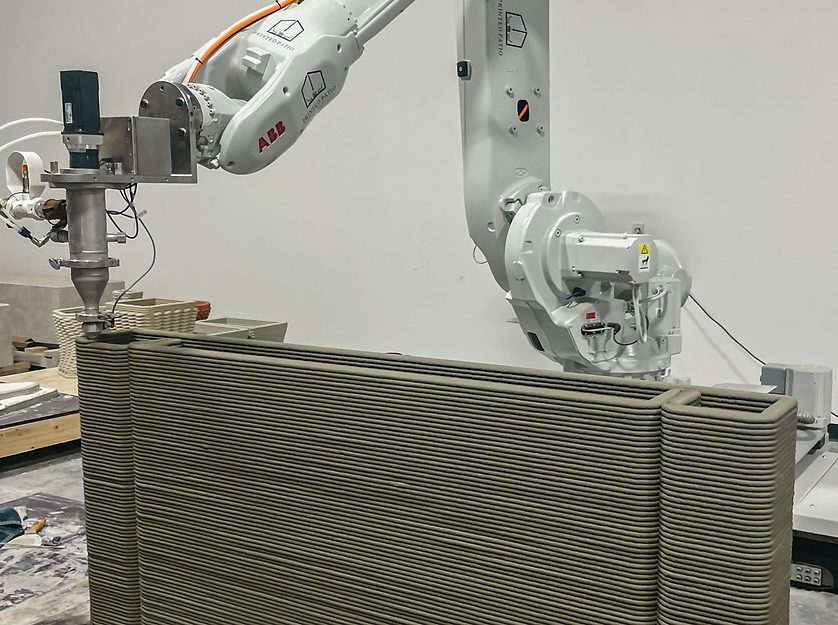

But on a much larger scale and with concrete as the “ink.” Guided by digital designs, a large robotic arm or printer nozzle moves along a predetermined path, extruding specially formulated concrete layer by layer to build walls and structural elements from the ground up.

This concrete quickly hardens, allowing for the construction of complex shapes and designs that traditional building methods would struggle to achieve. As each layer solidifies, the structure takes shape, creating entire buildings with reduced material waste and increased efficiency.

Big Island to Maui

Our 4th generation robotic printers excel in crafting exact corners and achieving a sleek finish, enabling us to print sections of walls. These sections are initially printed on the Big Island, then transported and assembled on Maui. This method is remarkably efficient, capable of producing an entire house in just a week. Sections are shipped in 20′ containers assembled on site with forklift.